본문

No.1954576

Environment-friendly Elastic Packaging Material Compositions Containing Oil-modified Alkyd Resin and A Construction Method of Elastic Packaging Materials Using Them

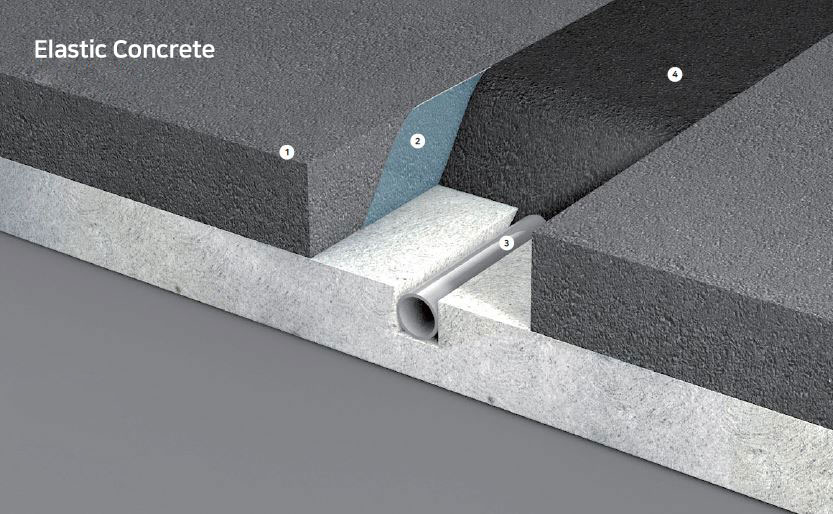

Overview of EC System

Overview of EC System

1.asphalt cutting

2.primer application

3.installation of a man of merit

4.elastomeric foam

Elastic concrete joints are formed with polyurethane materials of two ingredients and special aggregate. These joints can be used immediately just through mixing the main material, hardener and aggregate at the construction site, and they have a waterproof function with adhesion with regard to strong concrete. In addition, elastic concrete is used as fillers of expansion joints to absorb impulsive loads of vehicles, and equally conveys and distributes loads to lower structures. Elastic concrete which is highly ozone-resistant, chemical-resistant and abrasion-resistant is a material which is easy to work with.

Uses of Elastic Concrete EC

Uses of Elastic Concrete EC - Underground road joints

- For repairing concrete of highways, etc.

- For repairing concrete of harbors and waterfront

- Post-placing concrete for the block-out part of expansion joints

- For filling space

- Other parts that need waterproofing or absorb shock

Installation of Elastic Concrete EC

Installation of Elastic Concrete EC 1. Application of EC adhesive

Mix the EC adhesive and chemicals A and B sufficiently for two minutes using a drill mixer.

Apply it sufficiently on the surface where elastic concrete will be placed using a brush, roller, etc.

2. Installation of elastic concrete

Remove pollutants from the installation surface and mix A, B and C.

Mixing shall be done well for about 1-2 minutes using a tool with sufficient strength to prevent overload.

Elastic concrete shall be placed immediately on the installation surface, and placing shall be finished cleanly using tools, such as a plasterer.

Mixed elastic concrete shall be placed carefully so as not to flow down the inclined surface.

Photos of elastic concrete

Photos of elastic concrete (EC) construction